2024 John Deere 4066M Heavy Duty

|

|

The rear hitch on 4M Heavy-Duty Tractors provides producers with implement versatility to perform in a variety of applications. Attaching implements is convenient with telescoping draft links and Category 1 and 2 hitch balls in base equipment. The mechanical hitch control also features a depth stop and a rate of drop adjustment. This feature provides consistency when lowering the hitch. Each time the position control lever is pushed forward, it stops where the depth stop has been positioned. This is valuable to anyone who desires consistent, level ground. The 3-point hitch has plenty of lift capacity to handle heavy implements.

Category 1 and Category 2 hitches allow for hookup of a variety of 3-point hitch implements.

| ||||||||||||||||||||||||||||||||

|

RATE-OF-DROP/STOP VALVE

Rate-of-drop/stop valve regulates lowering speed of 3-point hitch. It can be shut off completely to stop hitch movement. TELESCOPING DRAFT LINKS (EXTENDABLE DRAFT LINKS)Telescoping draft links will reduce the amount of effort to attach 3-point hitch implements by allowing the operator to make small adjustments without moving the tractor. It is standard on 4M Heavy-Duty Tractors. Horizontal sway bar stabilizers regulate side-to-side sway of 3-point-hitch-mounted equipment.

Rockshaft position control lever allows operator to accurately set implement depth or height.

| ||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||

|

Maximize productivity with an eHydro™ transmission

| ||||||||||||||||||||||||||||||||

Safety features of the eHydro transmission include:

| ||||||||||||||||||||||||||||||||

|

|

|

Press button to active/deactivate eThrottle. When eThrottle is activated, depression of the travel pedal increases engine rpm and tractor speed. |

|

|

Press button to active/deactivate LoadMatch. When LoadMatch is activated, engine will not stall during heavy load applications. |

|

|

Press button to activate/deactivate SpeedMatch. When SpeedMatch is activated, operator is able to set the desired maximum travel speed. |

|

|

Press button to activate/deactivate cruise control. When cruise control is activated, operator is able to set cruise speed. |

|

|

Press button to set cruise speed, or to decrease cruise/set max speed. |

|

|

Press button to resume set cruise speed, or to increase cruise/set max speed. |

|

|

MotionMatch - longer accelerate and decelerate distances. |

|

|

MotionMatch - shorter accelerate and decelerate distances. |

eThrottle

eThrottle indicator

eThrottle indicator

Press a button to activate/deactivate eThrottle. When eThrottle is activated, depression of the travel pedal increases engine rpm and tractor speed simultaneously. This provides the operator with comfort and convenience as well as fuel economy.

Press a button to activate/deactivate eThrottle. When eThrottle is activated, depression of the travel pedal increases engine rpm and tractor speed simultaneously. This provides the operator with comfort and convenience as well as fuel economy.

AUTOMOTIVE-STYLE CRUISE CONTROL

Cruise control indicator

Cruise control indicator

An automotive-style cruise control is standard equipment on the 4M Heavy-Duty and 4R Series Tractors. Cruise control is electronically engaged and disengaged and is located on the right-hand operator console.

- Maintains desired forward speed without pressure on the foot pedal

- When activated, the operator is able to set cruise speed:

- Use the SET/- button to set cruise speed, or to decrease cruise/maximum speed

- Use the RES/+ button to set cruise speed, or to increase cruise/maximum speed

- A speed sensor also allows the tractor to maintain preset speed driving up and down hills

- To disengage the cruise control, either:

- Apply pressure to the brakes

- Disengage cruise control button

- Briefly depress the reverse travel pedal

LOADMATCH POWER MANAGEMENT SYSTEM

LoadMatch indicator

LoadMatch indicator

LoadMatch is a standard feature on the 4M Heavy-Duty and 4R Series Tractors.

If torque requirements increase significantly, the transmission will reduce the tractor's drive speed to compensate for the increased load on the transmission, maximizing torque to drive wheels and minimizing stalls.

Controls automatically adjust LoadMatch compensation depending on the tractor’s application. PTO applications require less engine speed fluctuation, therefore adjusting the amount of droop depending on PTO speed. This adjustment increases efficiency and optimizes engine speed and torque output based on tractor application.

While typically left on, LoadMatch can be turned off with the right-hand console controls.

MotionMatch

MotionMatch, standard on the 4M Heavy-Duty and 4R Series Tractors, is located on the right-hand console. It offers seven settings for adjusting the rollout or decelerating when the pedal is released.

MotionMatch indicator

MotionMatch indicator

This icon indicates longer accelerate and decelerate distances.

MotionMatch indicator

MotionMatch indicator

This icon indicates shorter accelerate and decelerate distances.

SPEEDMATCH

SpeedMatch indicator

SpeedMatch indicator

SpeedMatch, standard on the 4M Heavy-Duty and 4R Series Tractors, further enhances the eHydro cruise control functions by allowing the operator to preset maximum speed. Once this feature is engaged, the operator must stroke the travel pedal fully to meet the operator’s preset speed and press the Set button to lock the speed. From there, the operator can use the automotive-style cruise controls to adjust speed. This function will improve accuracy and safety, particularly at lower travel speed applications.

Rotary tilling or spraying applications are examples of where SpeedMatch can be applied. SpeedMatch will work in both the forward and reverse set speeds.

Increase productivity with integrated mid-mount loader selective control valve (SCV) and mechanical rear SCV

-

The tractor is base equipped with a dual mid SCV.

- Two sets of right-hand side-mounted couplers allow operating four hydraulic functions (such as raising/lowering boom and curling/dumping bucket).

- Large 12.7-mm (0.5-in.) diameter couplers are used for maximum oil flow to implements.

- Hydraulic valves have excellent featherability for smooth operation of equipment.

SINGLE REAR SCV

The tractor is also base equipped with a mechanical rear SCV with float function

One set of rear mounted couplers allow operating rear mounted hydraulic implements. Large 12.7-mm (0.5-in.) diameter couplers are used for maximum oil flow to implements. Hydraulic valves have excellent featherability for smooth operation of equipment.- Couplers are color coded for correct hookup.

- Hydraulic regenerative (REGEN) active, in dump position, out of neutral:

- Provides faster dump cycle

- Prevents cylinder voiding

OPTIONAL MID ELECTROHYDRAULIC THIRD SCV

OPTIONAL MID ELECTROHYDRAULIC THIRD SCV

Optional on the 4M Heavy-Duty Tractors is the factory-installed mid third-function SCV. This SCV adds versatility to tractor loader packages and enables the use of attachments such as a four-in-one bucket or root grapple.

The third function is controlled by a switch comfortably located on the loader joystick.

SCV CONTROLS

- Single control lever (A) makes operation of loader or other implements fast and simple.

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation.

- The SCV safety lock lever allows loader hydraulics to be locked out so the boom and bucket will not drop if SCV lever is accidentally bumped.

- The SCV safety lock lever allows loader hydraulics to be locked out so the bucket will not dump if SCV lever is accidentally bumped.

Powerful Yanmar® diesel engine delivers plenty of power under heavy loads

Powerful Yanmar® diesel engine delivers plenty of power under heavy loads

The Yanmar diesel engine has a high-torque reserve that provides plenty of power under heavy load.

This 4-cylinder engine features lower levels of exhaust emissions and reduced noise levels. It meets Environmental Protection Agency (EPA) Final Tier 4 (FT4) emission standards.

| Model | Number of cylinders | Engine displacement | Aspiration | Rated rpm | Gross engine hp* | Gross engine ps* | PTO hp |

| 4044M/R | 4 | 2.2L | Natural | 2600 | 42.5 | 43.1 | 32.5 |

| 4052M/MHD/R | 4 | 2.1 L | Turbocharged | 2600 | 50.8 | 51.5 | 39.9 |

| 4066M/MHD/R | 4 | 2.1 L | Turbocharged | 2600 | 65 | 65.9 | 52 |

*Engine hp (kW), gross SAE J1995: 43.1 (31.7) at 2600 rpm, PS Displacement, cu in. (L):134.25 (2.2)

*Engine hp (kW), gross SAE J1995: 51.5 (37.9) at 2600 rpm, PS Displacement, cu in. (L):128.15 (2.1)

*Engine hp (kW), gross SAE J1995: 65.9 (48.5) at 2600 rpm, PS Displacement, cu in. (L):128.15 (2.1)

The engine uses the latest technology to optimize fuel economy, improve control and accuracy, and reduce environmental impact.

The common rail system (CRS) optimizes fuel economy and reduces operating costs compared to engines not using CRS technology. High-pressure injection atomizes fuel into finer particles which burn more completely. It results in improved fuel economy and lower cost of operation.

The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions.

The engine comes with an aftertreatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC). After many hours of use, the exhaust filter may require an ash removal service.

DPF CLEANING

Depending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three conditions:

-

A prescribed time-based estimation of needed filter cleaning

-

DOC/DPF pressure sensors

-

A particulate matter buildup estimation based on load conditions

Once one of the three conditions have been met, filter cleaning will occur.

There are three different types of filter cleaning processes:

- Passive filter cleaning

- Active filter cleaning

- Parked filter cleaning

Passive filter cleaning

Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Active filter cleaning

If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then PM is removed using active filter cleaner. To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize PM.

It is important to note that at no time is the fuel in the DOC/DPF ignited, and there is no flame within the DOC/DPF.

Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Parked filter cleaning

In some instances where passive and active filter cleaning have not fully cleaned the PM from the system, a parked filter cleaning may need to take place. Most likely, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process.

The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See operator’s manual for more details.

This system constantly monitors the soot level of the tractor, making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage viewable on LCD display.

Key features of the engine are:

- 540-rpm power take-off (PTO) operation at 2600 engine rated speed means better fuel economy, less noise and vibration, and longer overall engine life

- Cast-in-block cylinder design for good cooling and long life

- Hydraulic lifters are quieter and require no adjustment

- Heavy-duty crankshaft provides more bearing surface area for added durability

- CRS optimizes fuel economy, lowering the cost of operation

- ECU provides optimum control and accuracy

- Direct fuel injection

- Improves starting

- Injects fuel directly on top of pistons for more efficient combustion

- Develops more horsepower per gallon of fuel

- Glow plugs (cold starting aid)

- Engine oil cooler, cools engine oil for longer engine life

- Key start and shutoff eliminates fuel shutoff knob

- Electric solenoid shuts fuel supply off immediately when key is turned off

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Sealed radiator compartment keeps trash and debris on outside of hood

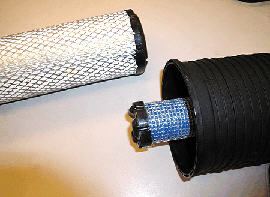

Dry-type air cleaner

Dry-type air cleaner

- Dry-type air cleaner with safety element and electronic air service indicator

- Electronic air restriction indicator alerts operator when air filter servicing is required

- Dual-element design for added engine protection

- Easy to service

- Standard side exhaust

- Discharges fumes away from the operator, reducing engine noise

- Improves operator visibility when using a loader or front implement

- Optional vertical exhaust

Yanmar is a trademark of Yanmar Company Limited.

Improved traction in muddy conditions with larger tires

Improved traction in muddy conditions with larger tires

Rain or shine, your work needs to get done. The 4M Heavy-Duty Tractor comes with larger, tougher tires to help keep you moving no matter what the weather brings.

- Offers two rear tire size options:

- 16.9-24 (8PR, R4 Industrial, two-position)

- 19.5L-24 (10PR, R4 Industrial, two-position)

- Allows for better traction in wet and muddy conditions

- Has a higher ply rating, which allows for better control and comfort when carrying heavy loads

| Engine power (gross) | SAE J1995 rated power: 48.5 kW 65 hp 65.9 PS at 2600 rpm |

|---|---|

| Power take-off (PTO) power | 38.7 kW 51.9 hp |

| Steering hydraulics | 23.5 L/min 6.2 gpm |

| Implement hydraulics | 42.3 L/min 11.2 gpm |

| Hitch type | Category 1/Category 2 |

| Lift capacity, 24-in. behind link arms | 1135 kg 2500 lb |

| Standard transmission; forward/reverse | eHydro transmission |

| Cruise control | Standard |

| Approximate shipping weight (open-station; cab) | Open station: 1950 kg 4290 lb Cab: Not applicable |

| Wheelbase | 185.5 cm 73 in. |

| Family | EYDXL2.09HDA FYDXL2.09HDA GYDXL2.09HDA |

|---|---|

| Manufacturer | Yanmar® |

| Engine model | 4TNV86CT-MJT |

| Engine power (gross) | SAE J1995 rated power: 48.5 kW 65 hp 65.9 PS at 2600 rpm |

| Power take-off (PTO) power | 38.7 kW 51.9 hp |

| Rated engine speed | 2600 rpm |

| Type | Diesel |

| Injection pump type | High-pressure common rail direct injection |

| Aspiration | Turbocharged and charge air cooled |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | 4 cylinders 2.091 L 127.6 cu in. |

| Number of cylinders | Four |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 86 x 90 mm 3.4 x 3.54 in. |

| Compression ratio | 19.1:1 |

| Lubrication | Pressurized |

| Cooling system | Liquid |

| Air cleaner | Dual element with electronic restriction indicator |

| Engine torque at rated speed | 178 Nm 131.3 lb-ft |

| Fuel tank capacity | 56.9 L 15 U.S. gal. |

| Battery size | 770 CCA |

|---|---|

| Alternator (12-V) | 75 amp |

| Starter size | 2 kW 2.68 hp |

| Type | High pressure common rail direct injection |

|---|

| Standard transmission; forward/reverse | PowrReverser transmission |

|---|---|

| Optional transmission; forward/reverse | eHydro transmission |

| Left-hand reverser | PowrReverser transmission only |

| Transmission gear ranges | 12F/12R PowrReverser Infinitely-variable, three range |

| Final drive | Planetary |

| Brakes | Multi-plate wet disc |

| Steering | Hydrostatic power steering |

| Clutch, wet/dry | Wet |

| Clutch disk diameter wet clutch | 129 mm 5.08 in. |

| Axle capacity | Front 1600 kg 3528 lb Rear 2400 kg 5292 lb |

| Creeper | No |

| Cruise control | Optional |

| Differential lock | Yes |

| Type | Open center |

|---|---|

| Pump rated output | Steering 23.5 L/min 6.2 gpm Implement 42.3 L/min 11.2 gpm 65.8 L/min 17.4 gpm |

| Pump type | Single gear |

| Draft control sensing | Position control |

| Remote control valves available | Up to six rear remotes |

| Type | Category 1 |

|---|---|

| Lift capacity, 24-in. behind link arms | 1135 kg 2500 lb |

| Standard | Independent 540 rpm at 2600 rpm |

|---|---|

| Control | Position |

| Clutch | Wet disc |

| Crankcase with filter | 5.3 L 1.4 gal. |

|---|---|

| Transmission and hydraulic system | 47.3 L 12.5 gal. |

| Type | Planetary |

|---|---|

| Differential lock | Yes |

| Rollover protective structure | Type Foldable Yes |

|---|---|

| Platform - flat/straddle | Flat |

| Gear shift location - console/floor | PowrReverser - Left-hand side |

| Wheelbase | 185.5 cm 73 in. |

|---|---|

| Front axle clearance | 35.1 cm 13.8 in. |

| Turning radius with brakes | 2.8 m 9.19 ft |

| Turning radius without brakes | 3.0 m 9.84 ft |

| Approximate shipping weight (open-station; cab) | OOS: 1705 kg 3759 lb Cab: Not applicable |

| Front | Farm - 8-16 Turf - 27x10.5-15 or 27x12LL-15 Industrial - 10-16.5 |

|---|---|

| Rear | Farm - 13.6-28 Turf - 44x18-20 or 22.5LL-16.1 Industrial - 16.9Lx24 |

| Front tread range | 148.1 cm 58.3 in. |

| Rear tread spacing | 137.2 cm 54 in. |

3-POINT HITCH CONTROL

3-POINT HITCH CONTROL

Rate-of-drop/stop valve shown on 4M Heavy-Duty Tractor

Rate-of-drop/stop valve shown on 4M Heavy-Duty Tractor

Danfoss eHydro transmission

Danfoss eHydro transmission INTEGRATED EHYDRO FEATURES

INTEGRATED EHYDRO FEATURES