2024 John Deere T670

- Single-point feederhouse latching

- Mass-flow sensor

- Reel resume in-cab control

- Easily remove fingers at rear of chaffer

|

|

The T-Series Combine is designed for high capacity. The T670 has a total sieve and chaffer area of 6.3 m² (67.8 sq ft) according to ISO Norm 6689: 1997, which is the largest cleaning shoe following the John Deere X9 Combines.

|

|

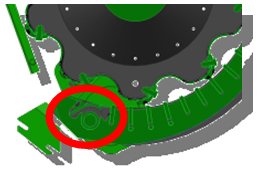

The quick-engage booster bar is adjustable from the outside via the stone trap with a 24-mm (0.95-in.) wrench. It has two positions. In the engaged position, the concave entrance features a profiled rasp bar. In the disengaged position, the concave entrance features a smooth transition plate. Adjustment can be completed easily within minutes. Material flow coming from the feeder house passing the booster bar is slowed down; this increases the threshing efficiency. The booster bar does not have a negative influence on the crop flow or the grain quality. The booster bar increases threshing efficiency in hard-to-thresh crops without closing the de-awning plates, allowing maximum separation at the concave area. |

|

The extra-fast unloading system provides a peak rate of 125 L/s (3.55 bu/sec) according to ISO 5687:1999 Norm. Compared to the John Deere S770 Combine’s unload rate of 116.3 L/s (3.3 bu/sec), the T670 has a faster unload rate that is also reflected in time saved when unloading on the headland. The extra-fast unloading system comes as the base option on the T670 Combine. Fast unloading on the go allows the operator to concentrate more on the crop by reducing unloading time. The higher unload rate is achieved by the grain tank cross augers, an increased discharge housing including vertical auger, larger sprockets and chain, and an overall higher speed of the unloading system. On the headland, the operator can reduce the rate by putting the machine at mid-idle or low idle; this allows for more precision, especially when the trailer is nearly full. |

|

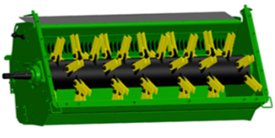

The improved extra fine cut straw chopper delivers excellent chopping quality and best-in-class residue distribution of chopped material in the field with a cutting width up to 10.7 m (35 ft) and 108 knives. The extra fine cut chopper comes standard with serrated chopper knives, which ensure superior splicing of the straw and improved straw rotting process. This chopper is highly recommended for producers with no tillage or minimum tillage operations. The optional dual-speed chopper drive provides flexibility to match all crops and conditions. |

|

John Deere is committed to setting new standards in connected agriculture because this offers tremendous potential to boost productivity, save valuable time, and lower costs.

|

|

With the John Deere satellite-based, hands-free AutoTrac™ steering system, every machine pass utilizes the full cutting width of your platform. This helps you save time and fuel and boost your combine performance – even at night, in dusty conditions, on hillside terrain, or after long hours of operation. The automatic steering relieves your operators and allows them to concentrate on productivity. When working with multiple machines in a field, the AutoTrac guidance lines can be shared from one machine to another so that all combines can harvest at the full cutting width. They can also be shared with the tractor or grain cart operator so the machines can drive exactly parallel to each other during unloading. With Interactive Combine Adjustment (ICA), you can increase the performance of your combine, minimize losses, avoid grain damage, and improve the quality of your straw. You can either optimize all parameters at the same time or focus on one. AUTOMATIC COMBINE ADJUST (ACA)Standard on all models within the T Series, Automatic Combine Adjust helps you effortlessly transition between crop types. By using standard John Deere values and retrieving data on your current threshing and separating conditions, it automatically adapts your machine to optimize performance. You can then use these proposed values or modify and save them for later use. HARVESTSMART™ SYSTEM – ALWAYS THE RIGHT SPEEDThe HarvestSmart system automatically adapts the speed of the combine to maximize capacity or minimize losses with the highest output. Sensors on the threshing cylinder, engine, and dedicated loss sensors control the system with the goal of minimizing losses or maximizing the throughput rate. |

| Engine type | John Deere PowerTech™ PSS engine 9.0 L 548 cu in. |

|---|---|

| Rated power | 292 kW 392 hp |

| Fuel capacity | 800 L 211 gal. |

| Concave area | 1.35 m2

14.5 sq ft |

| Separating area | 4 m2

43.1 sq ft |

| Total cleaning area (louvered) | 6.27 m2

67.5 sq ft |

| Grain tank size | 11,000 L 300 bu |

| Peak unloading rate | 115 L/s 3.3 bu/sec |

| Engine type | John Deere PowerTech PSS engine 9.0 L 548 cu in. |

|---|---|

| Emission level | Final Tier 4 (FT4) |

| Rated speed | 2200 rpm |

| Rated power | 292 kW 392 hp |

| Power boost @ rated speed | 25 kW 34 hp |

| Fuel capacity | 800 L 211 gal. |

| Drive type | Fixed |

|---|---|

| Conveyor chain slat type | Under shot slat |

| Length | 185 cm 73 in. |

| Feed Accelerator, Stone Trap (FAST) | Reverser Standard: 59 kW 79 hp Standard |

| Front chaffer | 0.6 m2

6.46 sq ft |

|---|---|

| Chaffer | 3.06 m2

32.9 sq ft |

| Sieve area | 2.64 m2

28.4 sq ft |

| Total cleaning area (louvered) | 6.27 m2

67.5 sq ft |

| Cleaning fan speed | Regular speed: 550 - 1350 rpm Slow speed: 300 - 600 rpm |

| Grain tank size | 11,000 L 300 bu |

|---|---|

| Unloading auger length | 7.05 or 8.7 m 23.5 or 28.5 ft |

| Peak unloading rate | 115 L/s 3.3 bu/sec |

| Country | Germany |

|---|

| Date collected | 04-May-2018 |

|---|