2024 John Deere 5105MH

|

|

OVERVIEWExperience ultimate operator experience in comfort and convenience by upgrading to the Premium Cab on 5M tractors. Upgrading to the Premium Cab unlocks a fixed panorama roof ideal for loader work. BENEFITS

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

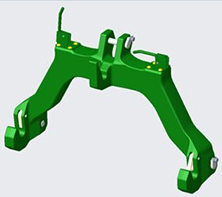

OVERVIEWHeavy-duty 3-point hitch provides lift capacity and adjustability for implement versatility with Category 2 implements or adaptable to Category 1. Precisely raise and lower heavy implements such as planters, sprayers, and field cultivators, using the rockshaft control lever. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop. BENEFITS

ADDITIONAL DETAILSMechanical or electrohydraulic hitch control operation Raise and lower rear implements with precision with either the mechanical or electrohydraulic (EH) hitch control. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop. OPTIONAL LARGER CYLINDERS:

SWAY BARS

Adjustable sway bars and telescoping draft links can be easily adjusted to adapt to a wide variety of implements. The right lift link also adjusts without tools for added convenience when leveling implements. REAR FENDER HITCH CONTROLS

Operators do not need to carry a tool to adjust the rear hitch. Operators can also raise and lower the 3-point hitch from outside of the tractor with the conveniently located rear fender hitch controls. REAR QUICK HITCH

An updated three-point quick hitch is offered on the 5M Tractors.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWAmple speeds and ease of operation for demanding applications with the 16F/16R PowrReverser, providing 16 forward speeds and 16 reverse speeds. This transmission comes standard with a dual speed 540/540 Economy power take-off (PTO), and it is ideal for applications requiring frequent directional changes, such as loader work. BENEFITS

ADDITIONAL DETAILS16F/16R transmission includes:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

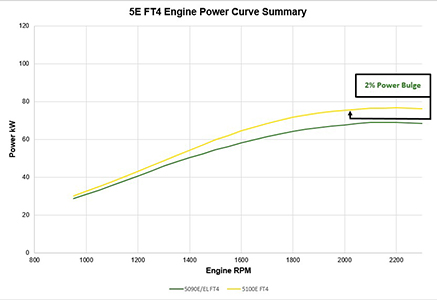

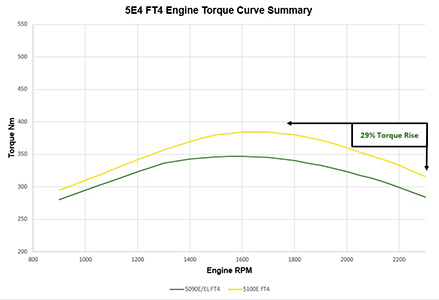

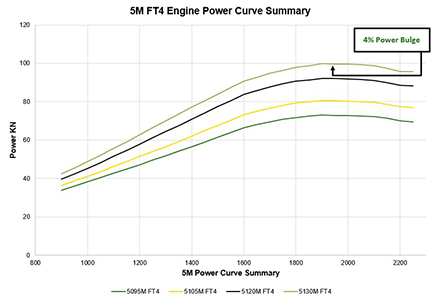

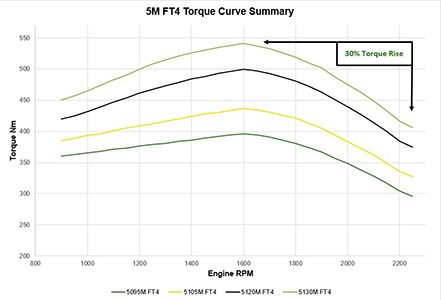

OVERVIEWWhen the tractor is under load, power bulge and torque rise work together to get through the tough spots without having to downshift. As rpm drops, the only way to maintain or increase horsepower is to provide additional torque. Whether bailing wet hay or lifting a heavy load, the additional power allows the tractor to continue performing the job without stopping. The rated economy power take-off (EPTO) speed occurs near the peak torque rise providing power when operator need it in PTO applications. BENEFITS

ADDITIONAL DETAILSHorsepower and torque are mathematically related.

5M 4-Cylinder tractors provide 4% power bulge while 5E 4-Cylinder tractors provide 2% power bulge. Note: There is no power bulge on 3-Cylinder tractors (5E 3-Cylinder or 5075M).

5E 4-Cylinder Power and Torque Curves

5M POWER AND TORQUE CURVES

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWOperators can view information in a crisp, vibrant, and useful array on the tractor instrument cluster. BENEFITS

ADDITIONAL DETAILSThere are daytime and nighttime modes which are based on the position of the light switch. The mode adjusts the backlight levels of the display for optimum visibility. |

| Engine description | John Deere PowerTech™ 4045 EWL |

|---|---|

| Engine displacement | 4 cylinders: 4.5 L 276 cu in. |

| Rated engine power | At 2200 rpm: 77.4 kW 105 hp |

| Maximum engine power | 80.6 kW 108.0 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: 66.2 kW 90 hp |

| Transmission type | PowrReverser™ 16F/16R with creeper |

| Hydraulic pump rated output | 94 L/min 24.7 gpm |

| Rear hitch category (SAE designation) | Category 2; convertible to 1 |

| Description | John Deere PowerTech™ 4045 EWL |

|---|---|

| Engine type | 4045HLV82 |

| Engine family | NJDXL04.5317 |

| Rated speed | 2200 rpm |

| Aspiration | Turbocharged/Air-to-Air Aftercooled |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| After treatment type | DOC/SCR |

| Displacement | 4 cylinders: 4.5 L 276 cu in. |

| Rated power | At 2200 rpm: 77.4 kW 105 hp |

|---|---|

| Rated PTO power (hp SAE) | At 2100 rpm: 66.2 kW 90 hp |

| Power boost | At 1900 rpm: 4 percent |

| Maximum engine power | 80.6 kW 108.0 hp |

| Engine peak torque | At 1600 rpm: 437 Nm 322 lb-ft |

| PTO torque rise | At 1600 rpm: 30 percent |

| Type | PowrReverser™ 16F/16R with creeper |

|---|---|

| Reverser | Left hand, electrohydraulic |

| Clutch; wet/dry | Wet |

| Creeper | PowrReverser™ 16F/16R with creeper |

| Type | Open Center |

|---|---|

| Pump rated output | 94 L/min 24.7 gpm |

| Available flow at a single rear SCV | 70 L/min 18.4 gpm |

| Number of rear selective control valves (SCVs) | Standard: Two Optional: Three |

| Number of mid selective control valves (SCVs) | Standard: Two Optional: Up to Three |

| Joystick SCV control | Mechanical |

| Hitch draft control load sense type | Mechanical or electrohydraulic |

|---|---|

| Remote control valves available | Standard: 2 Optional: 3 |

| Hitch category (SAE designation) | Category 2; convertible to 1 |

| Maximum lift capacity behind lift points | Standard: 2336 kg 5150 lb Optional: 2699 kg 5950 lb |

| Sensing type | Lower Link |

| Rear axle differential lock | Electrohydraulic |

| Type | Independent, 34.9 mm (1.375 in) Standard: 540/540 Economy (6 spline) Optional: 540/540E (6 spline) and 1000 rpm (21 spline) reversible shaft |

|---|---|

| Engine rpm (at rated PTO speeds) | 540 at 2100 rpm 540E at 1645 rpm 1000 at 2100 rpm |

| PTO actuation | Electrohydraulic |

| Type | High-Crop Flange Drop Axle |

|---|---|

| Final drive type | Inboard planetary |

| Differential controls | Electrohydraulic |

| Brakes, type and control | Hydraulic wet disc |

| Type | Mechanical Front Wheel Drive (MFWD) |

|---|

| Rear | MFWD: 230/95R48 R1W Radial |

|---|---|

| Wheel tread range | MFWD: 1340-1904 mm 52.8-75.0 in. |

| Turning radius with brakes | MFWD: 3.9 m 12.8 ft |

| Turning radius without brakes | MFWD: 4.7 m 15.4 ft |

| Alternator size | OOS: 90 amp Cab: 120 amp |

|---|---|

| Battery options | 12 V |

| Working lights | Standard: Halogen Optional: LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: Halogen Optional: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | Optional: LED |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, 2-post Platform - flat/straddle Flat Gearshift location - console/floor Floor |

|---|---|

| Seat | Standard: Mechanical Optional: Air Ride or Premium Air Ride |

| Instructional seat | Optional |

| Display | Automotive-style light-emitting diode (LED) instrument cluster |

| Radio | Optional |

| dB(A) rating | 78 dBA |

| Wheelbase | 2350 mm 92.5 in. |

|---|---|

| Overall length | 3996 mm 157.3 in. |

| Approximate shipping weight, Open;Cab | OOS: 4520 kg 9947 lb Cab:4710 kg 10364 lb |

| Fuel tank | Open: 140.8 L 37.2 U.S. gal. Cab: 140.8 L |

|---|---|

| Diesel exhaust fluid (DEF) tank | 12.0 L 3.17 U.S. gal. |

| AutoTrac ready | No |

|---|---|

| ISOBUS ready | No |

| Country of manufacture | Pune, India |

| Date collected | 6-Jan-2023 |

|---|

5M Tractor sway bars

5M Tractor sway bars 5M rear fender hitch controls

5M rear fender hitch controls Rear quick hitch

Rear quick hitch Sideview of quick hitch shown on 5M

Sideview of quick hitch shown on 5M

Left-hand reverser lever

Left-hand reverser lever Integrated declutch button on gear shifter

Integrated declutch button on gear shifter Creeper lever on 5MH only

Creeper lever on 5MH only

5E power curve summary

5E power curve summary 5E torque curve summary

5E torque curve summary 5M power curve summary

5M power curve summary 5M torque curve summary

5M torque curve summary