2024 John Deere 6105E

|

|

OVERVIEWFront and rear radial tire offerings are available on all models, except for the front tires on the open-operator station (OOS) configurations. BENEFITS

ADDITIONAL DETAILSTire combinations by model

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWTo further the versatility and efficiency of the 6E Tractors and their hydraulic capabilities, the 6Es (excluding 6120EH) can be ordered loader ready. Being able to add a loader to a 6E Tractor makes it an even more capable solution to the various tasks a utility tractor is challenged with.

Overview:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWAll John Deere 6E Series Tractors feature the reliable and proven 4.5L (275-cu in.) engines. These engines deliver constant power over a wide range of rpm with a power bulge above rated power and excellent torque characteristics.

Rated engine horsepower ratings are included for reference to competitor's gross or engine-only power ratings. There are several ratings systems used by other manufacturers. John Deere uses the horsepower-rating standard 97/68/EC, which is widely used in Europe for various regulations. How is engine-only rated and maximum power determined? John Deere engineering uses a precise procedure to measure engine-only power levels. The 97/68/EC standard is required in the European Union (EU) as an emission test, so there is some relation to the power a tractor has as a whole functioning unit; however, the procedure requires only that a production engine and radiator are used on a dynamometer test. Use the 97/68/EC horsepower ratings in the above chart to compare to competitor claims of engine-only power. Benefits of PTO power and power bulge

The John Deere exclusive single-injector control, electronic fuel injection system, and other key engine parts work together to sense engine load and instantly respond as needed to pull through tough spots. This reduces engine rpm fluctuation, resulting in the reduced need to downshift the transmission. Fewer shifts result in fewer ground variations, providing more overall tractor productivity. To match the engine power characteristics and improve economy of operation, the rated engine speed is 2200 rpm. FEATURE AND BENEFIT OVERVIEWHigh-pressure common rail fuel system

Four-valve cylinder head

Turbocharged

Turbochargers

Air-to-air intercooling

Compact size

Engine performance

John Deere electronic engine controls

Additional features

Details:

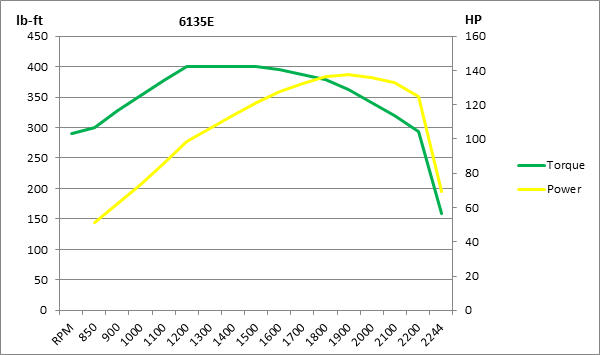

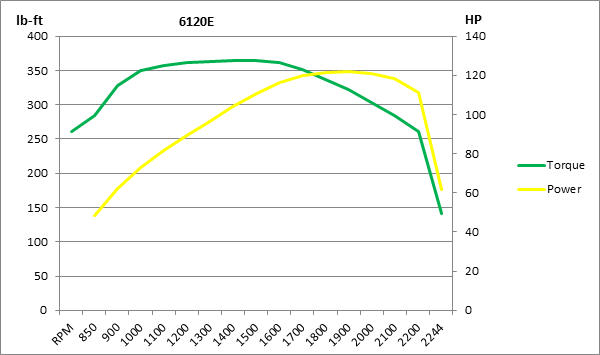

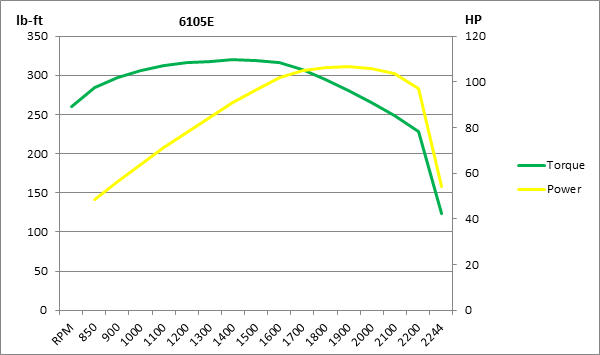

TORQUE CURVES

ENGINE SPECIFICATIONS

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

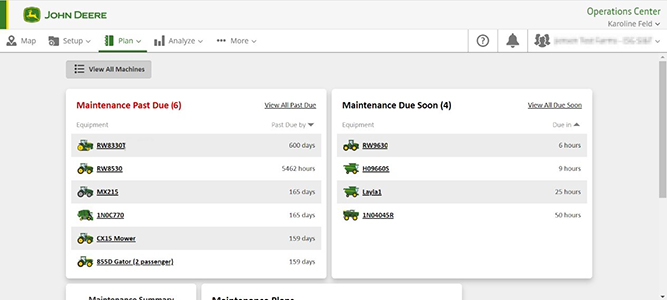

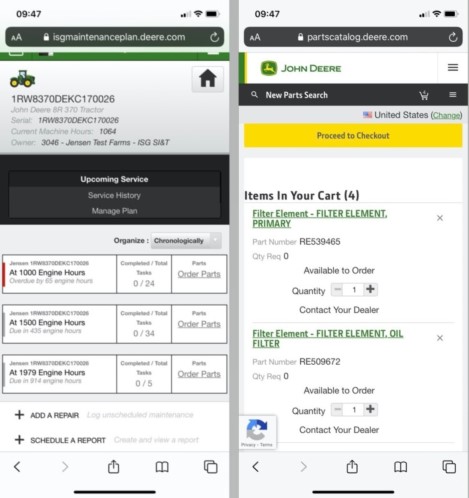

Make machine maintenance easy using tools in Operations Center Maintaining your equipment is easy with Maintenance in John Deere Operations Center web.

Maintenance in John Deere Operations Center web helps you manage maintenance for your equipment

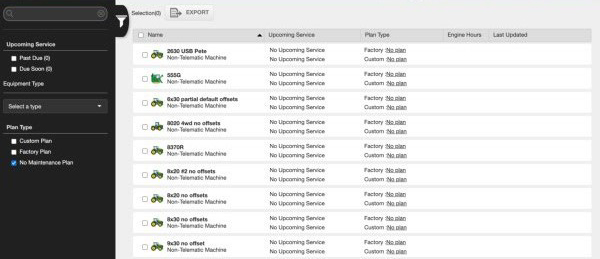

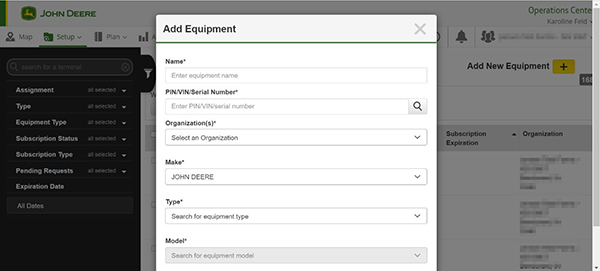

Add plans to non-telematic machines in Maintenance

Use Terminals to add non-telematic machines to your organization

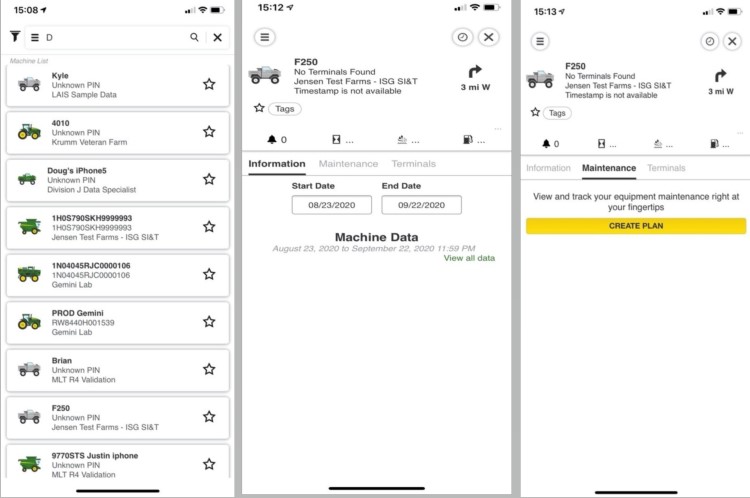

Use JDLink Mobile to view and edit maintenance plans

Select “Order Parts” to be directed to John Deere Parts and have the parts placed into your cart | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink. |

| Engine description | John Deere PowerTech™ PWL (B20 Diesel Compatible) |

|---|---|

| Engine displacement | 4.5 L 275 cu in. |

| Rated engine power | 97/68EC: 77 kW 105 engine hp |

| Rated PTO power (hp SAE) | 66 kW 89 PTO hp |

| Transmission type | Standard: John Deere 12F/12R PowrReverser™ Transmission: 30 km/h 19 mph Optional: John Deere 24F/12R PowrReverser Transmission: 40 km/h 25 mph |

| Hydraulic pump rated output | 36.5 cc pump: 75.7 L/min 20 gpm |

| Rear hitch category (SAE designation) | Category 2: 2500 kg (5500 lb) standard lift at 610 mm behind hitchpoint Optional: Category 2: 3318 kg (7300 lb) heavy duty lift at 610 mm behind hitchpoint |

| Description | John Deere PowerTech™ PWL (B20 Diesel Compatible) |

|---|---|

| Engine type | Diesel, in-line, 4-cylinders, wet-sleever cylinder lingers with 4 valves-in-head |

| Engine family | HJDXL04.5315 |

| Rated speed | 2200 rpm |

| Aspiration | Turbocharged, wastegate turbocharger with air-to-air aftercooling and cooled exhaust gas recirculation |

| Emission level | Final Tier 4 |

| After treatment type | DOC/DPF/SCR |

| Displacement | 4.5 L 275 cu in. |

| Rated power | 97/68EC: 77 kW 105 engine hp |

|---|---|

| Rated PTO power (hp SAE) | 66 kW 89 PTO hp |

| Engine peak torque | At 1,600 rpm: 432 Nm 318 lb-ft |

| PTO torque rise | 30 percent |

| Type | Standard: John Deere 12F/12R PowrReverser™ Transmission: 30 km/h 19 mph Optional: John Deere 24F/12R PowrReverser Transmission: 40 km/h 25 mph |

|---|

| Type | Open-center Gear driven |

|---|---|

| Pump rated output | 36.5 cc pump: 75.7 L/min 20 gpm |

| Available flow at a single rear SCV | 75.7 L/min 20 gpm |

| Number of rear selective control valves (SCVs) | Standard: ISO Couplers: 2 Optional: ISO Couplers 3 |

| SCV control | Mechanical |

| Hitch category (SAE designation) | Category 2: 2500 kg (5500 lb) standard lift at 610 mm behind hitchpoint Optional: Category 2: 3318 kg (7300 lb) heavy duty lift at 610 mm behind hitchpoint |

|---|---|

| Maximum lift capacity behind lift points | Standard: Category 2 with heavy duty lift: 3318 kg 7300 lb |

| Sensing type | Optional |

| Type | Independent Standard: 35 mm (1.375 in.) 540 rpm/1000 rpm reversible shaft |

|---|---|

| Engine rpm (at rated PTO speeds) | 2085 engine rpm at 540 rpm PTO 2067 engine rpm at 1000 rpm PTO |

| Type | Flange |

|---|---|

| Final drive type | Inboard Planetary |

| Rear differential lock | Full-locking mechanical |

| Type | Standard: MFWD Optional: 2WD |

|---|---|

| Front axle differential lock | 2WD: None MFWD: limited slip |

| Wheel tread range | 2WD: 1533-2043 mm 60.4-80.4 in. MFWD: 1516-2016 mm 59.7-79.4 in. |

|---|

| Alternator size | 90 amp |

|---|---|

| Battery options | 12 V |

| Total cold cranking amps | 925 CCA |

| Seat | Standard: Mechanical suspension cloth seat Optional: Air suspension |

|---|---|

| Instructional seat | Optional |

| Display | LCD instrument cluster |

| Wheelbase | 2WD: 2456 mm 96.7 in. MFWD: 2450 mm 96.5 in. |

|---|---|

| Approximate shipping weight, Open;Cab | 2WD: Open: 4064 kg 8960 lb MFWD: Open: 4268 kg 9410 lb Cab: 4645 kg 10,240 lb |

| Fuel tank | 165.4 L 43.7 U.S. gal. |

|---|---|

| Diesel exhaust fluid (DEF) tank | 12.0 L 3.17 U.S. gal. |

| Country of manufacture | Mexico |

|---|

| Date collected | 9-Feb-17 |

|---|

6135E torque curves graph

6135E torque curves graph 6120E(H) torque curves graph

6120E(H) torque curves graph 6105E torque curves graph

6105E torque curves graph