2024 John Deere 5075E

|

|

Jobs seem easier when you are comfortable and the premium cab on the 5E 3-Cylinder Tractor is designed for you to enjoy. No matter the weather, the Premium Cab is ready for you to climb in and explore the value in the same-sized utility tractor to get the job done. With exclusive features like sunroof with sunshade, Electronic Quick Raise-Lower (EQRL) hitch controls, Go-Home Lighting, and loaded with features that are extras on a standard cab, this 5E Cab has lots to experience.

NOTE: Auxiliary power strip field kit shown is not included in Premium Cab image at top left.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Simplify repetitive rear hitch lifting and lowering tasks with the Electric Quick Raise Lower (EQRL) on 5E 3-Cylinder Premium Cabs. EQRL uses one button to raise to transport height and another to lower the rear hitch back to your prescribed depth.

EQRL efficiency gains:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

No regen required with final tier 4-compliant PowerTech™ engines on 5E 3-Cylinders

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEW5E 3-Cylinder Series Tractors can be equipped with as many as five (up to two rear and three mid) economical and versatile spool-type SCVs. These SCVs provide a high-flow rate for the tractor's hydraulic system with the open-center hydraulic system. BENEFITS

ADDITIONAL DETAILS

Rear SCVs

The valves are a stackable design and controlled by color-coded levers at the operator's right hand. The single SCV features a detented float position, while the two rear SCV’s first valve features a detented float position and the second valve has a regenerative position. Mid-mount SCVs

Mid-mount SCVs are the recommended option for loader operation and feature a detented float position on the first valve and a regenerative position on the second valve for faster loader bucket dump cycles. Add more versatility to loader with a third function allowing use of grapple, 4-in-1 bucket, or other loader implements requiring additional hydraulic function. Factory-installed triple mid-SCV available starting with model year 2023 provides true third function over previously available field-installed diverter kit (2+1 function). Also starting with model year 2023 the dual mid-SCV has a stackable design to allow for future upgrade to a triple mid-SCV if third loader function is required. Each valve features extend, retract, neutral, and float positions and is controlled by a unique joystick-control lever mounted on the operator's right-hand side. Mid-SCV joystick-control lever

Tractors that are equipped with dual or triple mid-mount SCVs are controlled by a user-friendly and ergonomic joystick, operating independently of the rear SCVs.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWAmple speeds and ease of operation for demanding applications with the 12F x 12R PowrReverser. This transmission comes standard with a dual speed 540/540 economy power take-off (E-PTO) is ideal for applications requiring frequent directional changes such as loader work. BENEFITS

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWIncrease drawbar pull and improve traction when operating in slippery conditions with a limited-slip, heavy-duty MFWD front axle. BENEFITS

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Made of heavy-duty steel for added reliability, the 2WD front axle is adjustable in 50.8-mm (2-in.) increments to adapt to a wide variety of applications.

Broadening the 5E 3-Cylinder Tractor product lineup to offer a 2WD front axle in a cab configuration provides you with the well-known benefits of the 5E 3-Cylinder Tractors in conjunction with the ability to stay out of the elements and have the tighter turning radius that 2WD front axles provide. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWThe SyncShuttle transmission is designed to match the excellent power and torque characteristics of the John Deere PowerTech™ engines. The 9F/3R SyncShuttle provides nine forward and three reverse speeds with in-line synchronized shuttle shifting. BENEFITS

ADDITIONAL DETAILAdditionally, the in-base transmission is configured with fixed draft links, single-speed power take-off (PTO) and mechanical PTO engagement. The transmission is characterized as full top shaft synchronized (TSS) when forward shifting on-the-go between speeds and is characterized a synchronized while depressing the clutch.

Creeper available as field installed kit with following speeds in km/h.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OVERVIEWPower an implement at 540 PTO rpm at a lower tractor engine rpm with Economy PTO (540E PTO). Depending on the transmission, the 540E PTO engine requirement could be as low as 1588 rpm. 540E PTO is ideal for many lighter-duty applications including mowing or spraying that do not require full engine horsepower. BENEFITS

ADDITIONAL DETAILS

How does 540E PTO work? To operate in economy mode, the shiftable 540/540E lever must be in 540E and then the throttle can be increased to the appropriate rpm. When in 540E, the tractor has a throttle limiter that keeps the operator from increasing engine rpm over the 540E setting. The limiter is used to prevent accidental over-speeding of PTO implements and protection against binding the PTO shaft. Details on the engine rpm required for standard 540 and 540 economy mode can be found in the operator’s manual along with additional details on operation and adjustment. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The stationary PTO enable switch is in base for all 5000 Utility Tractors produced starting on 1 November 2020 (except for the 5E 3-Cylinder Tractors with 9F/3R transmission which began in November 2021). The PTO shuts down if the operator leaves the seat with the PTO on. Stationary operation of a tractor PTO-powered implement allows the operator to leave the driving position with the PTO engaged by pressing the stationary PTO enable switch. See operator’s manual for additional details on operation and adjustment. Refer to the chart below for models with the stationary PTO enable switch in base. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Engine description | John Deere PowerTech™ 3029 EWR |

|---|---|

| Engine displacement | 3 cylinders: 2.9 L 179 cu in. |

| Rated engine power | At 2100 rpm: 50.4 kW 75 hp |

| Maximum engine power | 55 kW 75 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: OOS 39.6 kW (53 hp) Cab 36.6 kW (49 hp) |

| Transmission type | Standard: SyncShuttle™ 9F/3R Optional: PowrReverser™ 12F/12R |

| Hydraulic pump rated output | 68.8 L/min 18.2 gpm |

| Rear hitch category (SAE designation) | Category 2; convertible to 1 |

| Description | John Deere PowerTech™ 3029 EWR |

|---|---|

| Engine type | 3029HPY110 |

| Engine family | NJDXL02.9339 |

| Rated speed | 2100 rpm |

| Aspiration | Turbocharged |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| After treatment type | DOC/EGR |

| Displacement | 3 cylinders: 2.9 L 179 cu in. |

| Rated power | At 2100 rpm: 50.4 kW 75 hp |

|---|---|

| Rated PTO power (hp SAE) | At 2100 rpm: OOS 39.6 kW (53 PTO hp) Cab 36.6 kW (49 PTO hp) |

| Power boost | 0 percent |

| Maximum engine power | 55 kW 73.7 hp |

| Engine peak torque | At 1500 rpm: 280 Nm 206 lb-ft |

| PTO torque rise | 21 percent |

| Type | Standard: SyncShuttle™ 9F/3R Optional: PowrReverser™ 12F/12R |

|---|---|

| Reverser | SyncShuttle™: No PowrReverser™: Yes |

| Clutch; wet/dry | SyncShuttle™: Dry PowrReverser™: Wet |

| Creeper | Kit available for OOS SyncShuttle™ 9F/3R transmission |

| Type | Open center |

|---|---|

| Pump rated output | 68.8 L/min 18.2 gpm |

| Available flow at a single rear SCV | 43.1 L/min 11.4 gpm |

| Number of rear selective control valves (SCVs) | Standard: One Optional: Two |

| Number of mid selective control valves (SCVs) | Standard: Zero Optional: Up to Three |

| Joystick SCV control | Mechanical |

| Hitch draft control load sense type | Mechanical |

|---|---|

| Remote control valves available | Standard: One Optional: Two |

| Hitch category (SAE designation) | Category 2; convertible to 1 |

| Maximum lift capacity behind lift points | 1448 kg 3192 lb |

| Sensing type | Top link |

| Type | SyncShuttle™: Independent 540 PowrReverser™: Independent 540/540E |

|---|---|

| Engine rpm (at rated PTO speeds) | 540 at 2100 rpm 540E at 1588 rpm |

| PTO actuation | SyncShuttle™: Mechanical (lever) PowrReverser™: Electrohydraulic |

| Type | Flange |

|---|---|

| Final drive type | Planetary |

| Differential controls | Mechanical (pedal) |

| Brakes, type and control | Hydraulic wet disc |

| Type | Standard: Two-Wheel Drive (2WD) Optional: Mechanical Front Wheel Drive (MFWD) |

|---|

| Rear | 2WD: 16.9-28 R1 Bias MFWD: 16.9-28 R1 Bias |

|---|---|

| Turning radius with brakes | 2WD: 3.1 m 10.2 ft MFWD: 3.94 m 12.9 ft |

| Turning radius without brakes | 2WD: 3.5 m 11.5 ft MFWD: 4.65 m 15.3 ft |

| Alternator size | OOS: 70 amp Cab: 110 amp |

|---|---|

| Battery options | 12 V |

| Working lights | Halogen |

| Type of bulb in headlight (Halogen, Zenon, LED) | Halogen |

| Type of bulb in beacon (Halogen, Zenon, LED) | Kit: Halogen |

| ollover protective structure, OOS | Rigid - foldable - telescopic Foldable, 2-post Platform - flat/straddle Straddle Gearshift location - console/floor Floor, on the side |

|---|---|

| Seat | Standard: Mechanical Premium Cab: Air Ride |

| Instructional seat | Optional |

| Display | Simple automotive-style instrument cluster |

| Radio | Optional |

| dB(A) rating | 81 dBA |

| Wheelbase | 2WD and MFWD: 2050 mm 80.7 in. |

|---|---|

| Overall length | 3639 mm 143.3 in. |

| Approximate shipping weight, Open;Cab | 2WD OOS: 2520 kg 5555 lb 2WD Cab: 2989 kg 6590 lb MFWD OOS: 2735 kg 6029 lb MFWD Cab: 3090 kg 6812 lb |

| Fuel tank | OOS: 72.5 L 19 U.S. gal. Cab: 82 L 21 U.S. gal |

|---|---|

| Diesel exhaust fluid (DEF) tank | Not Applicable |

| AutoTrac ready | No |

|---|---|

| ISOBUS ready | No |

| Country of manufacture | Sub assembly in Pune, India, Final assembly in Augusta, GA |

| Date collected | 6-Jan-2023 |

|---|

Light the way as you Go-Home from your day

Light the way as you Go-Home from your day

Single rear SCVt

Single rear SCVt Dual rear SCV

Dual rear SCV Dual mid-mount SCVs on OOS tractors

Dual mid-mount SCVs on OOS tractors Triple Mid-SCV with 520M loader lines installed

Triple Mid-SCV with 520M loader lines installed Joystick-control mid-mount SCVs on OOS tractorst

Joystick-control mid-mount SCVs on OOS tractorst Third function button on joystick control

Third function button on joystick control

ADDITIONAL DETAIL

ADDITIONAL DETAIL

ADDITIONAL DETAILS

ADDITIONAL DETAILS

Synchronized shifting in all forward and reverse gears

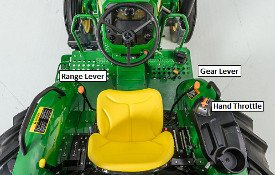

Synchronized shifting in all forward and reverse gears Range selection pattern

Range selection pattern

STATIONARY OPERATION OF THE REAR PTO WITH OPERATOR OUT OF SEAT

STATIONARY OPERATION OF THE REAR PTO WITH OPERATOR OUT OF SEAT